Hydrostatic and Pressure Testing

Hydrostatic testing is an invaluable way to assess the strength and integrity of pressured systems, guaranteeing they can meet operational demands without fail. Hydrostatic testing can be used to evaluate pipes, tanks, or vessels by filling them up with water under pressure before applying pressure in order to detect leaks or problems that might exist within these items.

Hydrostatic pressure testing is essential in multiple industries, from plumbing to industrial pipelines. Hydrostatic testing helps avoid expensive failures or leaks by verifying that systems can meet specified pressure levels safely.

The Importance of Accurate Hydrostatic Testing

Accurate hydrostatic testing is essential to assuring the safety and efficiency of pressurized systems, from pipes, tanks, and pressure vessels to pressurized storage facilities. Not only does hydrostatic pressure testing detect potential leaks; but it also verifies their durability by replicating real world operating conditions in its testing procedure.

Leak detection, which detects minor flaws or cracks early, helps avoid costly system failure. Hydrostatic testing provides another useful means of evaluating new installations as well as monitoring current ones for durability and state.

Plumbing, oil & gas and HVAC industries rely heavily on accurate hydrostatic testing to meet stringent safety and performance requirements. By adhering to industry law, these industries can avoid expensive repairs, environmental hazards and ensure compliance with safety procedures.

Key Challenges in Hydrostatic Testing

Hydrostatic Testing Hydrostatic testing is an integral component of business. But while hydrostatic testing can provide significant value, there can be various challenges which hinder its accuracy and efficiency. One common difficulty of hydrostatic testing involves testing large systems - like huge pipelines or industrial vessels where access may be restricted - where access is limited. Also, using outdated or insufficient tools may result in inaccurate pressure readings and reduced leak detection.

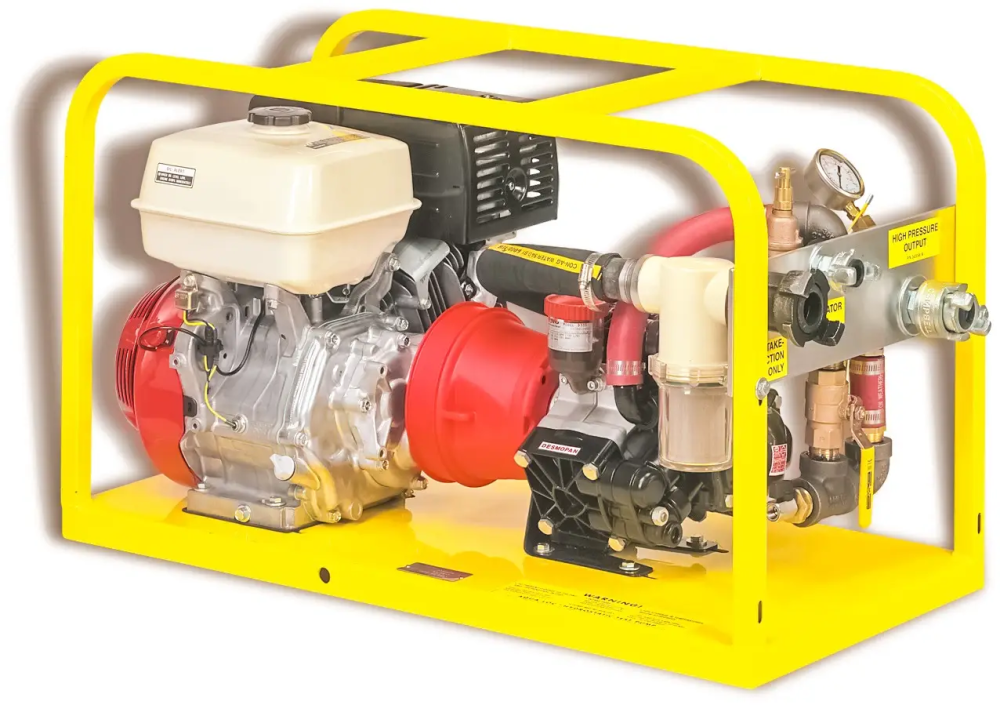

To overcome these obstacles, it is crucial to employ tools specifically tailored for hydrostatic testing. High-pressure pumps and precise gauges are all indispensable in maintaining correct pressure levels throughout testing procedures for more reliable results and increased overall safety.

Effective Solutions for Hydrostatic Pressure Testing

Numerous tools are utilized to efficiently perform hydrostatic testing in various industrial settings. This equipment helps facilitate testing while also guaranteeing accurate measurements. Reliable and long-lasting testing equipment plays an essential role in producing consistent, reproducible results across a broad spectrum of applications.

- High-Pressure Pumps: High-pressure hydrostatic pumps are essential equipment for hydrostatic pressure testing as they create the pressure necessary for testing, assuring systems are thoroughly examined.

- Pressure Gauges: Pressure gauges can be used to monitor pressure levels throughout a test, detecting any variances or irregularities that may exist in real time.

- Diaphragm Pumps: Diaphragm pumps can be ideal for portable and effortless operation in remote locations, making their use ideal.

Businesses that invest in top-of-the-line hydrostatic testing gear can increase testing accuracy, maintain safety standards and enhance system reliability.

Why Select Reliable Equipment?

Selecting reliable tools for hydrostatic pressure testing is critical to obtaining accurate results and assuring the safety of pressurized systems. Quality equipment has a dramatic effect on testing efficiency and dependability.

High-quality pumps designed specifically for hydrostatic testing can produce exceptional pressure levels, which allow for full examinations of pipelines and vessels. Versatile testing solutions allow specialists to adapt quickly to various testing situations and requirements, increasing operational efficiency.

Utilizing appropriate equipment makes testing procedures faster and simpler, enabling workers to concentrate more on test execution than equipment issues.

Get in Touch for Reliable Hydrostatic Pressure Test Solutions

Hydrostatic testing is essential in protecting the integrity and safety of pressurized systems, with improper testing leading to significant problems that pose significant safety risks, while neglecting it could cause costly repairs and extended downtime.

Petersen Products provides reliable hydrostatic testing solutions and gadgets tailored specifically for your needs, making us your one-stop source. Get in touch with us at sales@petersenproducts.com or 262-692-3100; our knowledgeable staff is on hand to ensure your systems run efficiently! We look forward to hearing from you.