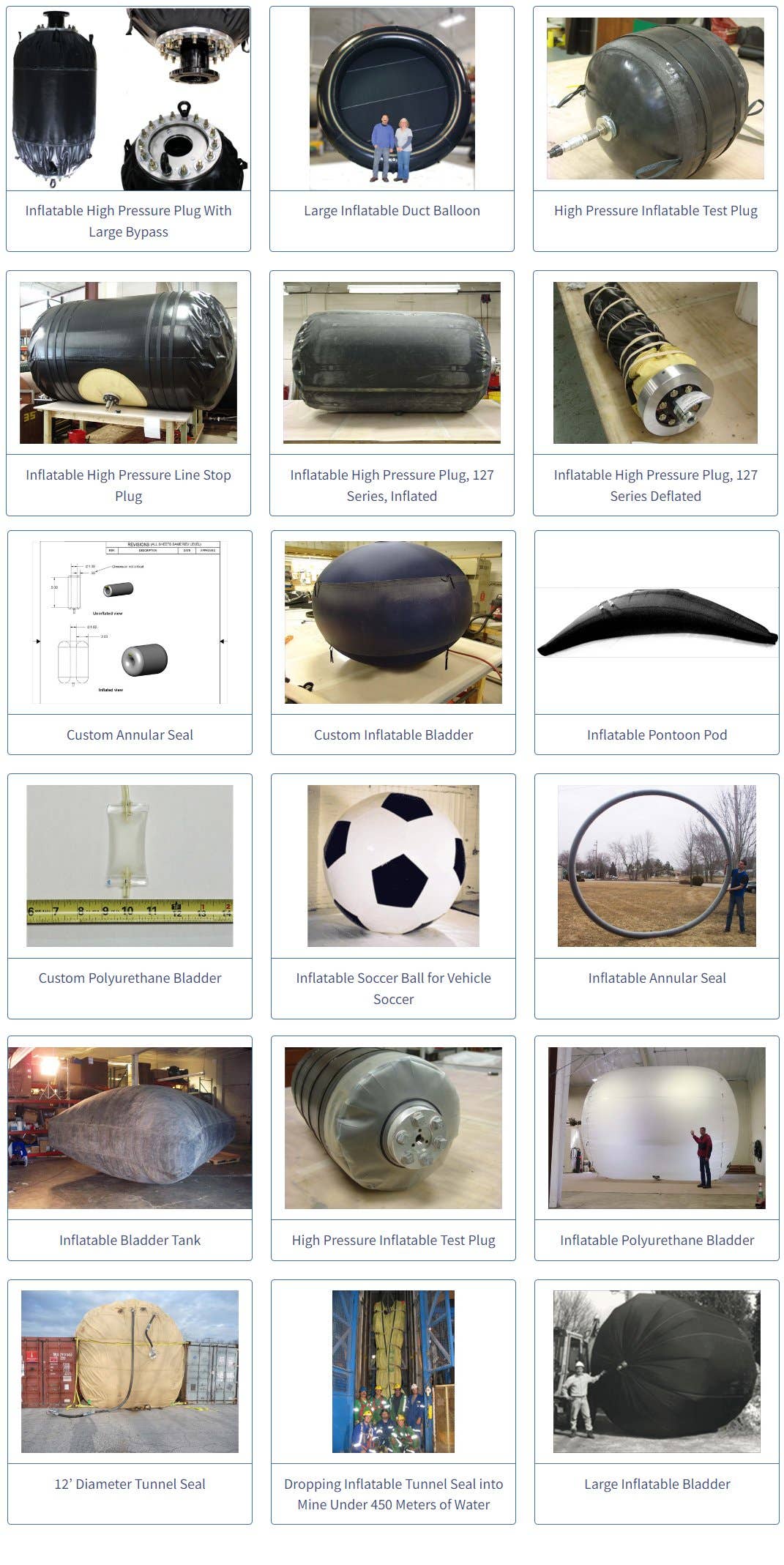

Bladders and Custom Inflatables

Custom flexible and inflatable products are available from materials applicable to most temperature and chemical requirements. A few of the many woven and non-woven materials used in the past include Canvas, EPDM, Kevlar, Neoprene, Nitrile, Nylon, Polyurethanes, Polyester, Polyethylene, Polyvinylchloride, Viton, Viton Extreme, etc.

To receive a quick quote click here or call 888-945-7342 / 888-945-7342

What are Inflatable Bladders?

An inflatable bladder is a versatile, flexible device designed to contain, redirect, or control fluids or gases by inflating within a confined space. Thes inflatable bladders are constructed from durable materials such as reinforced rubber, nylon, or composite fabrics, these bladders are engineered to expand when filled with air or another medium.

Their inflation creates a pressure seal or provides support in various applications which provides a reliable solution in environments where traditional rigid components are not helpful. Inflatable bladders are highly adaptable which allows them to be customized in shape, size, and material to fit specific needs. They are used in situations where precision, flexibility, and easy setup are crucial.

Why Choose Inflatable Bladders Over Traditional Options?

Inflatable bladders offer several key benefits that make them a better choice than traditional rigid options. They are more versatile, easier to use, and can be adapted to different situations. These features make inflatable bladders ideal for both temporary and long-term use in a wide range of industries.

Here’s why inflatable bladders are a smart choice:

1. Flexibility and Adaptability – Inflatable bladders are highly flexible and adaptable which makes them suitable for various applications where rigid structure are not useful.

2. Ease of Deployment – These Inflatable bladders are lightweight and easy to deploy and can be easily inflated or deflated when needed. Due to this, they are an ideal option for temporary or emergency applications, reducing installation time and labor expenses.

3. Customizability - Inflatable bladders can be customized to specific operational requirements by changing their shape, size, and material. This level of customization guarantees that the bladder works well in its intended environment.

4. Portability - When deflated, inflatable bladders are compact and easy to transport making them ideal for applications where mobility is important. They can be stored in a small space and carried to different locations without much effort.

5. Durability – These bladders are made from robust materials like reinforced rubber or composite fabrics, to withstand harsh conditions such as extreme temperatures, chemicals, and physical stress. Their durability often matches or exceeds that of traditional rigid options.

6. Versatility – Inflatable bladders are used across variety of industries for many applications such as construction, healthcare, marine and more. Due to their versatility, they are used in multiple scenarios outperforming traditional solutions in harsh conditions.

These benefits make inflatable bladders a great option for a wide range of applications, offering not only effective but also efficient and cost-effective solutions.

Types of Inflatable Bladders Available at Petersen Products

Inflatable Air Bladder

An inflatable air bladder is a flexible, air-filled device designed to create a seal, provide support, or control the flow of liquids or gases. These bladders are lightweight, easy to use, and can be inflated quickly. They are commonly used for sealing pipes, lifting objects, or providing temporary support in applications like construction, plumbing, and manufacturing.

Inflatable Bladder Tanks

An inflatable bladder tank is a flexible, collapsible container which is designed to store and transport liquids such as water, chemicals, or fuels. These bladder tanks are made from durable, reinforced materials which can be safely inflated to store large volumes of liquid. These inflatable bladder tanks are used in various applications like water & fuel storage, agriculture & more industrial uses.

Custom Inflatable Bladders

A custom inflatable bladder is designed to meet specific requirements for a particular job or application. These bladders can be customized in terms of size, form, and material to suit the task at hand. Custom bladders provide a versatile solution when typical solutions don't meet the project's specific requirements.

Applications of Inflatable Bladders

Inflatable bladders are versatile tools used across various industries due to their ability to conform to different shapes and sizes, and their ease of deployment. Below are some of the key applications:

1. Construction and Civil Engineering

- Sealing and Blocking: Used to temporarily seal pipes or ducts during maintenance.

- Water Control: Create temporary dams or barriers to manage water flow.

- Lifting and Supporting: Assist in lifting heavy objects or providing support on construction sites.

2. Marine and Offshore

- Buoyancy Control: Provide buoyancy for vessels or underwater structures.

- Salvage Operations: Lift sunken objects from the seabed.

- Underwater Repairs: Seal leaks or hold structures during repairs.

3. Automotive and Aerospace

- Crash Testing: Simulate impact forces in vehicle safety tests.

- Fuel Storage: Serve as flexible fuel tanks in aircraft or spacecraft.

- Safety Systems: Integral to airbag deployment systems.

4. Medical and Healthcare

- Patient Support: Used in medical mattresses and cushions to prevent bedsores and provide comfort.

FAQs

1. How do I determine the right material for my inflatable bladder?

The choice of material for an inflatable bladder depends on the specific application and environmental conditions. Factors such as temperature, chemical exposure, and physical stress must be considered. Common materials include EPDM for weather resistance, Kevlar for high strength, and Neoprene for flexibility. Consult with a manufacturer to select the best material for your needs.

2. Can inflatable bladders be used in high-pressure applications?

Yes, inflatable bladders can be designed for high-pressure applications. The material and construction need to be selected based on the pressure requirements. Manufacturers can provide custom solutions that meet the pressure specifications of your application.

3. What maintenance is required for inflatable bladders?

Regular maintenance includes inspecting for leaks, ensuring proper inflation levels, and checking for wear and tear. Cleaning the bladders according to the manufacturer's recommendations helps prolong their lifespan. Avoid exposing them to harsh chemicals or extreme temperatures unless they are specifically designed to handle such conditions.

4. How long do inflatable bladders typically last?

The lifespan of an inflatable bladder varies depending on the material, usage, and environmental conditions. Proper maintenance and adherence to usage guidelines can extend their durability. Manufacturers can provide expected lifespan estimates based on typical usage scenarios.

5. What factors should be considered when customizing an inflatable bladder?

When customizing an inflatable bladder, consider factors such as the bladder's intended use, required size and shape, material compatibility with substances it will come into contact with, and the operating environment. Providing detailed specifications and consulting with a manufacturer can ensure the custom inflatable bladder meets all requirements.

- Low Pressure Gas Plugs, 154 Series

- Multi-Flex® High Expansion Gas Bag Style Pipe Plug, 113 Series

- Multi-Flex® High Pressure Block & Bleed Plugs, 127BB Series

- Multi-Flex® High Pressure Hydrocarbon Resistant Inflatable Pipe Plugs, 127 Series

- Multi-Flex® Oil Resistant With & Without Bypass Pipe Plug, 114-115 Series

- Multi-Flex® Oil-Resistant Heavy-Duty Pipe Plug, With & Without By-Pass, 124-125 Series

- Municipal Style By-pass Plugs Sizes, 130-2 Series

- PeteStop® Pipe Plug, Inflatable Flow Stop, 129-8 Series

- PeteStop® Pipe Plug, Inflatable Line Stop, 128 Series

- PeteStop® Pipe Plug, Inflatable Line Stop, 129 Series

- Point Repair Packer Carrier with & without By-Pass, 130-5 Series

- Rigid Core Remote Placement Bore Hole Plugs & Packers, 126 Series

- Rubber Aramid Reinforced Pipe Plugs, 136 Series

- Rubber Leak Detector Test Plugs, 130-4 Series

- Rubber Long Test Plugs, 130-3 Series

- Rubber Pillow Style Test Ball Plugs, 130-9 Series

- Rubber Plugs with Large Flow-Through By-Pass,130-6 Series

- Rubber Plumber Test Plugs, 130-0 Series

- Rubber Plumber Test Plugs, With & Without By-Pass, 137 Series

- Rubber Remote Placement Plugs, 130-7 Series

- Rubber Stack Test Plugs, 130-1 Series

- Through the Valve Line Stop

- Effluent Pumps & Accessories

- Hose Assemblies

- Inflation Controllers For Pipe Plugs and Packers - 936 Series

- Mechanical Plug Safety Gags, 936-5 Series

- Pipe Plug Inflation Accessories

- Pipe Plugs and Packers Accessories Pull Cages, 936 Series

- Rotating Elbows for Gas and Fluid Systems, 936 Series Petersen®

- ABS & SS Threaded Pipe End Test Plug, 143-8 Series

- ABS End of Pipe Gripper Plug, 143-9 Series

- Bolt Type High Pressure Test Plugs, 147 Series

- Bolt Type Medium Pressure Test Plugs With By-Pass, 146-9 Series

- Custom Mechanical Plugs, 145-2 Series

- EZ-Swet Mechanical Line Stopper Plugs, 148-0 Series

- Flush Mounted & Beveled Finishing Plate Plugs, 140-4 & 140-5 Series

- Hand Tightening Aluminum Body Flexible Double Test Plugs, 149-2 Series

- Hand Tightening Aluminum Body Test Plugs With By-Pass, 149-1 Series

- Hand Tightening Double Seal Wing Nut, 141-2 Series

- Hand Tightening Low Pressure Aluminum Body By-Pass Plugs, 141 Series

- Hand Tightening Low Pressure Nylon Plug, 144 Series

- Hand Tightening Nylon Pipe Plug, 142-0 Series

- Hand Tightening Nylon Test & Cleanout Plugs, 143-0 Series

- High Impact ABS Wing Nut Plug, 144-1 Series

- High Lift Flange Weld Test Plugs, 151-Series

- High PSI Double Block & Bleed Single Actuator, 145-1 Series

- Lever Type Expandable Rubber Plugs, 143-1 Series

- Mechanical High Pressure Test Plugs, 145-9 Series

- Monitor Well Plugs, 142-8 Series

- Pipe Protector Bell or Spigot End, 140 Series

- Pipeline Joint Tester, 24in to 120in, 145-8 Series

- Polypropylene End of Pipe Plugs, 143-4 Series

- Remote Placement Expander Plugs,148-3 Series

- Rubber Seal Mechanical Pipe Plugs, 143-2 Series

- Steel Wing Nut Pipe Plugs, 143-3 Series

- T-Handle Aluminum Test Plugs with & without By-Pass, 143-7 Series

- Tapered Redwood Pipe Plugs, 140-1 Series

- Test Caps, 142-9 Series

- Water Line Stub Plugs, 143-5 Series

- Wing Nut Hand Tight Test Plugs, 141-1 Series

- High Pressure Portable Hydrostatic Test Pumps, 938-9 Series

- Hydrostatic Test Pumps, 938-93 Series

- Leak Detector Pressure Testing, 924-1304 Series

- Leak Detector Pressure Testing, 924-1304 Series

- Manhole Vacuum Test Equipment, 938-7 Series

- Parachutes, Stringers, Ventilators, Smoke Blowers

- Pipeline Deflection Gauges, 938-96 Series

- Pipeline Joint Testers, Sizes 24" to 120", 145-8 Series

- Smoke Testers, 938-95 Series

- Smoke Testers, 938-95 Series