Custom Manufacturing Solutions

Petersen has engineers for design and a wide variety of manufacturing capabilities to produce custom and standard products and components from a wide variety of materials.

Petersen has engineers for design and a wide variety of manufacturing capabilities to produce custom and standard products and components from a wide variety of materials. Petersen creates mechanical and inflatable solutions for industries including pipeline, power, chemical, oil & gas, refining, wastewater, municipal water, and aerospace.

Equipment includes:

- CNC Lathes

- CNC Mills

- CNC Fabric Pattern Cutting

- Manual Mills & Lathes

- RF Welding Inflatables

- Custom O-Rings From Most Elastomers

- Custom Vulcanizing

- Custom Molds and Molding

- Heavy Fabric Sewing Equipment

- Mechanical and Inflatable Assembly

Contact Petersen with your requirements or ideas and let our engineers and manufacturing capabilities work for you. We love to create solutions to the most intractable challenges.

Technology and Services

- Solidworks

- MasterCam

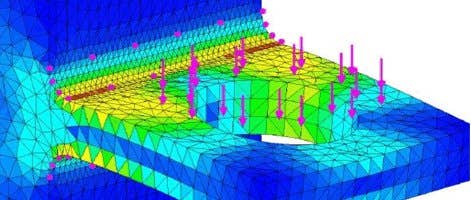

- Finite Element Analysis (FEA)

- Root Cause and Failure Analysis

- Monarch Pressure Testing System

- ERP system and integrated e-commerce platform

- ISO 9001:2015 Quality Program

- Inventory management

- Export and Import Compliance

- Inspection and Engineering

- Project Management

Machining

- 2018 Twinhorn VH-1010 CNC - 4th Axis and right angled head W20” X L40” X H21.5”

- 2016 Twinhorn VTJ-1680 CNC mill - 4th Axis W29.5” X L60” X H31.5”

- 2006 Doosan Puma 2500LY live tooling lathe - 10” chuck, 12” max turn, 3” thru spindle, 32” max turn length, Y-axis

- 2013 Femco HL-55S big bore Lathe - 15” chuck, 20” max turn, 4.5” thru spindle, 48” max turn length

- 2014 Doosan Puma 2600LY live tooling lathe with bar feeder - 10” chuck, 14” max turn, 3” thru spindle, 32” max turn length, 5’ bar feeder, Y-axis

- 2011 Doosan Lynx 220LM live tooling lathe with bar feeder - 6” chuck/ collet system, 10” max turn, 2” thru spindle, 20” max turn length 4’ bar feeder

- 2017 Cosen auto feeding CNC saw - 13” dia. Round, 14” square, auto feeding

- Do-all band saw - 16” throat 12” height of cut

- Harrison Manual lathe - DRO 10” chuck, 11” max turn, 2.5” thru spindle, 30” max turn length

- Lagun Manual Mill - DRO W18” X L40” X H16”

- Fast Tapper

- OD Grinder

- Various calibrated gages and measuring devices

- Die threading machine

Metal Fabrication

- Lincoln Plasma Cutter

- GMAW/FCAW/GTAW/SMAW welding machines

- Cutting Torch

- Pedestal grinders

- Mag-based drill

- Arbor press - 20" stroke

- Shop prime and paint

Rubber and Plastic Fabrication

- Various foams, plastics, and rubber products

- 20 and 30 Mil Polyurethane Film

- Various raw plastic and rubbers such as Nitrile, EPDM, and Viton

Typical Stocked Materials

- Aluminum bar stock, tube, and plate

- Export worthy plywood and lumber

- Ballistic Nylon w/ various engineered coatings such as Polyurethane, Nitrile, and EPDM

- Canvas including military grades

- Kevlar w/ various engineered coatings such as EPDM and Viton

Choose a category

- Low Pressure Gas Plugs, 154 Series

- Multi-Flex® High Expansion Gas Bag Style Pipe Plug, 113 Series

- Multi-Flex® High Pressure Block & Bleed Plugs, 127BB Series

- Multi-Flex® High Pressure Hydrocarbon Resistant Inflatable Pipe Plugs, 127 Series

- Multi-Flex® Oil Resistant With & Without Bypass Pipe Plug, 114-115 Series

- Multi-Flex® Oil-Resistant Heavy-Duty Pipe Plug, With & Without By-Pass, 124-125 Series

- Municipal Style By-pass Plugs Sizes, 130-2 Series

- PeteStop® Pipe Plug, Inflatable Flow Stop, 129-8 Series

- PeteStop® Pipe Plug, Inflatable Line Stop, 128 Series

- PeteStop® Pipe Plug, Inflatable Line Stop, 129 Series

- Point Repair Packer Carrier with & without By-Pass, 130-5 Series

- Rigid Core Remote Placement Bore Hole Plugs & Packers, 126 Series

- Rubber Aramid Reinforced Pipe Plugs, 136 Series

- Rubber Leak Detector Test Plugs, 130-4 Series

- Rubber Long Test Plugs, 130-3 Series

- Rubber Pillow Style Test Ball Plugs, 130-9 Series

- Rubber Plugs with Large Flow-Through By-Pass,130-6 Series

- Rubber Plumber Test Plugs, 130-0 Series

- Rubber Plumber Test Plugs, With & Without By-Pass, 137 Series

- Rubber Remote Placement Plugs, 130-7 Series

- Rubber Stack Test Plugs, 130-1 Series

- Through the Valve Line Stop

- Effluent Pumps & Accessories

- Hose Assemblies

- Inflation Controllers For Pipe Plugs and Packers - 936 Series

- Mechanical Plug Safety Gags, 936-5 Series

- Pipe Plug Inflation Accessories

- Pipe Plugs and Packers Accessories Pull Cages, 936 Series

- Rotating Elbows for Gas and Fluid Systems, 936 Series Petersen®

- ABS & SS Threaded Pipe End Test Plug, 143-8 Series

- ABS End of Pipe Gripper Plug, 143-9 Series

- Bolt Type High Pressure Test Plugs, 147 Series

- Bolt Type Medium Pressure Test Plugs With By-Pass, 146-9 Series

- Custom Mechanical Plugs, 145-2 Series

- EZ-Swet Mechanical Line Stopper Plugs, 148-0 Series

- Flush Mounted & Beveled Finishing Plate Plugs, 140-4 & 140-5 Series

- Hand Tightening Aluminum Body Flexible Double Test Plugs, 149-2 Series

- Hand Tightening Aluminum Body Test Plugs With By-Pass, 149-1 Series

- Hand Tightening Double Seal Wing Nut, 141-2 Series

- Hand Tightening Low Pressure Aluminum Body By-Pass Plugs, 141 Series

- Hand Tightening Low Pressure Nylon Plug, 144 Series

- Hand Tightening Nylon Pipe Plug, 142-0 Series

- Hand Tightening Nylon Test & Cleanout Plugs, 143-0 Series

- High Impact ABS Wing Nut Plug, 144-1 Series

- High Lift Flange Weld Test Plugs, 151-Series

- High PSI Double Block & Bleed Single Actuator, 145-1 Series

- Lever Type Expandable Rubber Plugs, 143-1 Series

- Mechanical High Pressure Test Plugs, 145-9 Series

- Monitor Well Plugs, 142-8 Series

- Pipe Protector Bell or Spigot End, 140 Series

- Pipeline Joint Tester, 24in to 120in, 145-8 Series

- Polypropylene End of Pipe Plugs, 143-4 Series

- Remote Placement Expander Plugs,148-3 Series

- Rubber Seal Mechanical Pipe Plugs, 143-2 Series

- Steel Wing Nut Pipe Plugs, 143-3 Series

- T-Handle Aluminum Test Plugs with & without By-Pass, 143-7 Series

- Tapered Redwood Pipe Plugs, 140-1 Series

- Test Caps, 142-9 Series

- Water Line Stub Plugs, 143-5 Series

- Wing Nut Hand Tight Test Plugs, 141-1 Series

- High Pressure Portable Hydrostatic Test Pumps, 938-9 Series

- Hydrostatic Test Pumps, 938-93 Series

- Leak Detector Pressure Testing, 924-1304 Series

- Leak Detector Pressure Testing, 924-1304 Series

- Manhole Vacuum Test Equipment, 938-7 Series

- Parachutes, Stringers, Ventilators, Smoke Blowers

- Pipeline Deflection Gauges, 938-96 Series

- Pipeline Joint Testers, Sizes 24" to 120", 145-8 Series

- Smoke Testers, 938-95 Series

- Smoke Testers, 938-95 Series