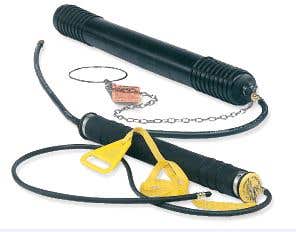

Pipe Plug, Rubber, Long Test 130-30 Series

Made from natural rubber, these long test ball plugs feature a ring and chain assembly that keeps plugs from entering the line during deflation. These pipe plugs are offered with a 3' extension hose.

| Image | Dia. Max | Dia. Deflated | By-Pass | Infl. Press. Required | Press. Pipeline Max | Length Deflated | Port, Inflation | Shipping Wt. | Item Number | Price | Qty | Action |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

6.25" (159mm) | 3" (76mm) | None | 45 psi (3.10 bar) | 13 psi (0.9 bar)/30' (9.1 m) | 28.5" (724mm) | Schrader Tire Valve on a 3ft hose | 4 Lbs (1.81 Kg) | 130-306-M |

$140.00

|

||

|

6.25" (159mm) | 4.12" (105mm) | None | 30 psi (2.07 bar) | 13 psi (0.9 bar)/30' (9.1 m) | 28.25" (718mm) | Schrader Tire Valve on a 3ft hose | 6 Lbs (2.72 Kg) | 130-306- |

$240.00

|

||

|

4.25" (108mm) | 2.5" (64mm) | None | 30 psi (2.07 bar) | 13 psi (0.9 bar)/30' (9.1 m) | 24.75" (629mm) | Schrader Tire Valve on a 3ft hose | 3 Lbs (1.36 Kg) | 130-304- |

$112.00

|

||

|

3.25" (83mm) | 2.31" (59mm) | None | 35 psi (2.41 bar) | 13 psi (0.9 bar)/30' (9.1 m) | 20.75" (527mm) | Schrader Tire Valve on a 3ft hose | 2 Lbs (0.91 Kg) | 130-303- |

$92.80

|

||

|

2.25" (57mm) | 1.5" (38mm) | None | 45 psi (3.10 bar) | 13 psi (0.9 bar)/30' (9.1 m) | 18.25" (464mm) | Schrader Tire Valve on a 3ft hose | 2 Lbs (0.91 Kg) | 130-302- |

$72.20

|

Benefits of Using Inflatable Test Ball Plugs

Petersen Products’ test ball plugs are designed for waste stack testing and seal the rise and the run to perform the test. They are also used to seal the wye to conduct sewer air tests. The following are a few benefits of using inflatable test ball plugs offered by Petersen Products Company.

- Durability: These long test ball plugs are made from natural rubber, making them long-lasting and robust.

- Compatibility: They are compatible with PVC pipes, making the wye fittings easy while performing DWV tests. The multi-size design of these ball plugs makes them compatible with various pipe diameters, making them an easy choice for different plumbing systems.

- Effective Sealing: These test ball plugs provide a tight seal, ensuring accurate leak detection and pressure testing in DWV systems.

- Safety: Ring and chain assembly prevents the plug from being drawn into the DWV system during testing.

- Advanced Design: The MM series of rubber test ball plugs inflates and deflates in stages and is available in multi-stage designs. They help keep the area dry by preventing water from oozing out of the pipe riser during deflation process.

Applications

Our plumbing test balls are used in the following applications:

- Waste stack testing from floor drains to sewer pipes

- Pressure testing and blocking residential drain-waste-vent (DWV) systems

- Repair and maintenance of municipal infrastructure

Don't Wait - Get Your Inflatable Test Ball Plugs Today!

Ready to upgrade your plumbing tests? Contact us for more information, or place your order now! Our team is here to assist you with any queries and ensure you get the best solution for your DWV system testing needs.

Frequently Asked Questions on Long Test 130-30 Series & MS2 Series Long Test-Ball Plugs Sizes

- What are test ball plugs?

They are expandable rubber test plugs used to test drain, vent, and waste systems in every type of pipe. - What is the difference between an MS-2 Long Test Ball and a Long Ball?

These products are designed for sealing wye fittings during sewer testing. However, they slightly differ in terms of their features. For instance, the MS-2 Long Test Balls feature a relief valve, which automatically deflates or inflates during the testing and helps keep the work area dry and clean. - What are the temperature limits for operating a pneumatic pipe plug handle?

Our pipe plug handles can withstand temperature ranges from 0°F to 125° F (-17.7°F to 51.667°C). - How should I determine the plug size?

The pipe plugs have a maximum and minimum sealing (usage) size range. So, before buying, ensure that the pipe’s inside diameter matches with the plug’s sealing range. Our MS2 Series plugs are compatible with multiple pipe diameters. - How to use test plugs?

- Here are the steps of operation of test plugs:

- Place the plug in the application or the pipe to be blocked at a distance equal to their diameter.

- Connect one end of the inflation hose to the inflation fitting of the plug and the other end to pump, line pressure, or supply pressure device.

- If your application has a second fitting, connect another hose to this fitting. The other end of the hose should be connected to a calibrated gauge.

- Ensure to brace or block the plug appropriately before inflating it for testing.

- Next, you must carefully introduce pressure to the plug through the inflation hose. The plug should only be inflated to the rated inflation pressure listed on it.

- Allow the plug to stabilize for a few seconds. You can further inflate it to match the rated inflation pressure if needed.

- You can begin by testing the pipe or application. Once this ends, release the back pressure behind the plug from outside the danger zone.

- After releasing all back pressure, relieve the pressure from outside the danger zone until the plug deflates properly.

- Remove the bracing system or block and remove the plug from pipe. Follow the instructions for storage.

- Why should I consider the calculation of pounds of force?

This calculation will help you understand the forces behind the plug, which in turn will help you understand the proper way to block it. - Are all plug sizes repairable?

The plugs without sealing rings can be repaired easily and are eligible for patching. A plug can be patched only four times, maximum. Damage longer than 4? cannot be patched, and it should not be deep enough to penetrate the cording. In addition to patching, you can also make other repairs, such as replacing inflatable bladders, bypass castings, hoses, and fittings. - Is it necessary to check the inflation pressure of plugs?

Yes, it is. The inflation pressure of the plug must be checked once every 4 hours when it is in use. - What does the term “feet of head” mean?

This shows the height of water over the center line of the plug. - What are the maintenance and storage instructions for test plugs?

Here are a few maintenance and storage instructions for test plugs:- Clean the plug with mild soap and water after every use.

- Inflate plug to 1PSIG to inspect it. Do not inflate it beyond the recommended 1PSIG when it is outside the pipe as this may damage the plug.

- Observe the plug for any signs of wear, cut, or deterioration. Do not use a damaged plug.

- Keep the plug in a dry place away from sunlight or other sources of UV light and ozone. Plugs are suspended vertically or placed horizontally below 110°F (43°C).

References

https://www.oatey.com/products/cherne-ms2-long-testball-1502061842

https://www.cherneind.com/products/cherne-ms2-long-testball-1502061842

https://www.cherneind.com/products/cherne-long-testball-1728509090

https://www.cherneind.com/safety